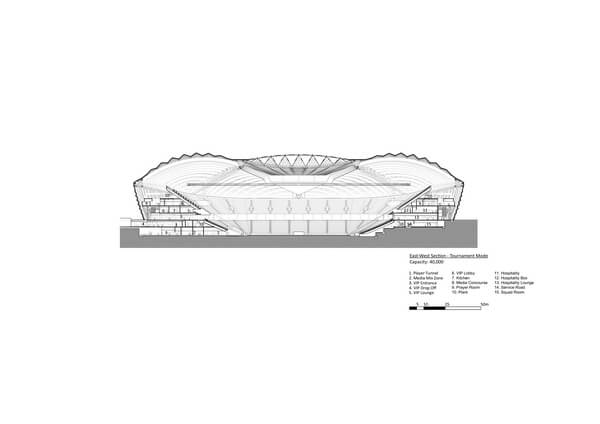

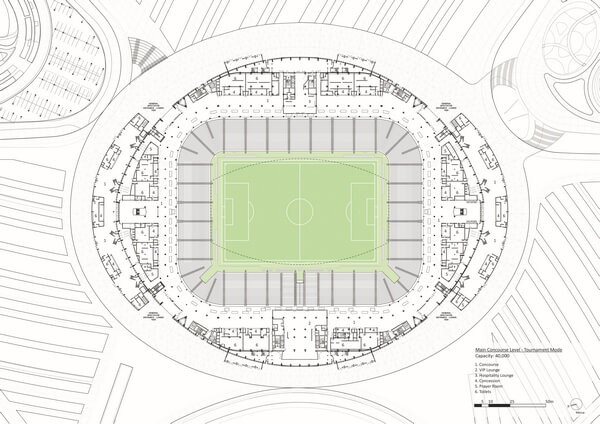

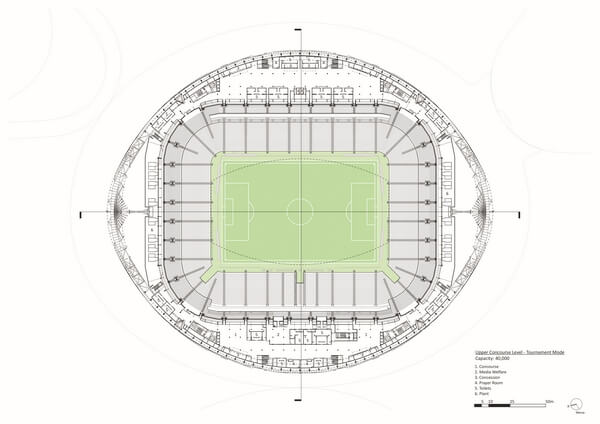

赛时容量:40,000人

距多哈市中心:23km

设计理念:设计灵感来自传统单桅帆船,是对沃克拉航海历史的致敬。创新的冷却系统和可伸缩屋顶意味着体育场将全年使用。 体育场由建筑师扎哈·哈迪德本人参与设计。

联赛模式:FIFA2022年卡塔尔世界杯™四分之一决赛场地。

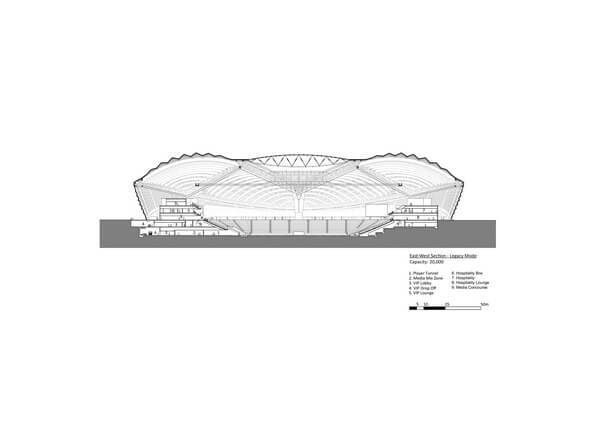

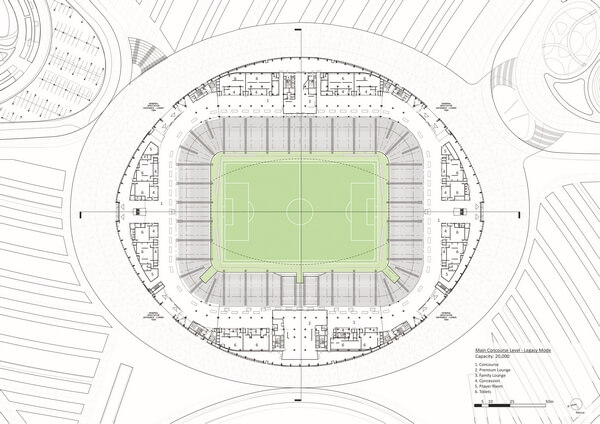

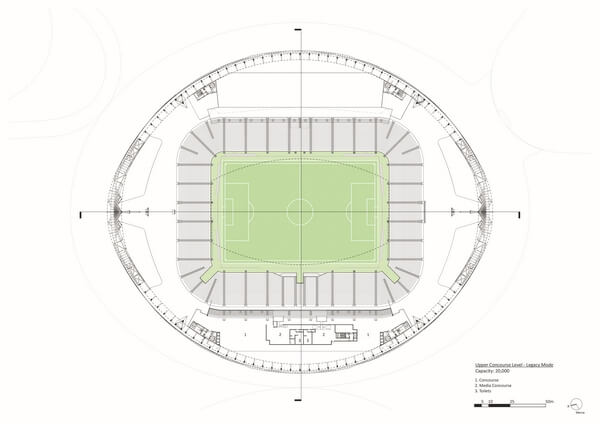

遗留模式:世界杯后会作为沃克拉体育俱乐部主场。由于其模块化特性,赛后体育场的容量将减少到20,000个座椅,多余的座椅(主要为上层观众席)将捐赠给海外的足球发展项目。

片区设施:涵盖各种体育设施,包括自行车道和跑道、骑马区和绿化带。此外,还有一个市场和部分社区设施,如清真寺和学校等。

开幕典礼:该体育场于2019年5月16日举办2019年阿米尔杯决赛。

主承包商:MIDMAC、Sixco和PORR卡塔尔的合资企业。

项目经理:KEO国际咨询公司

促进当地经济:许多卡塔尔公司参与了沃克拉市贾努布球场的交付,包括MIDMAC和PORR卡塔尔、制造体育场座椅的Coastal 公司和制造所需钢材的Sulb公司。超过50%的体育场建设投资推动了卡塔尔当地的经济。

冷却技术:贾努布球场采用了由卡塔尔专家设计和交付的,创新的太阳能驱动冷却方案。

太阳能驱动的暖通和空调(HVAC)系统将使用座椅下的通风口为观众席提供低速冷却循环。在上下两层之间平均分配的100多个通风口将服务于整座体育场。体育场HVAC系统的冷却源头来自于区域冷却系统的冷却水。观众坐席区的最大流速为1m/s。

球场范围的冷却系统共包括8个空气处理单元(AHU):4个在东侧,4个在西侧。每个单元馈送都将连接到观众座位下方延伸的增压室。然后增压室向多个喷嘴提供空气,这些喷嘴将空气传送到球场并进入比赛场地。球场范围水平的最大流速为10m/s。

交通:贾努布体育场位于新高速公路和道路网络之中,无论从沃克拉市还是多哈市,居民和游客都可轻松抵达。场馆最近的地铁站是多哈市Red Line线的沃克拉地铁站,站点离场馆4.5km,比赛日期间有摆渡车穿梭提供服务。除此以外,这里还有专用公交车站,交织的自行车道和安全的人行道。

可持续性:贾努布体育场已获得三项可持续性认证:

1)国际可持续评估系统(GSAS)设计和建造证书——可持续设计四星级;

2)GSAS施工管理证书A级*可持续性评级,认可项目在施工期间为保护环境所做的广泛努力;

3)能源中心的季节能效比证书。

球场:铺设在比赛场地的草皮是在沃克拉市草坪农场种植的。球场草坪于3月首次铺设,仅花费9小时15分钟的工时也因此创下了纪录。

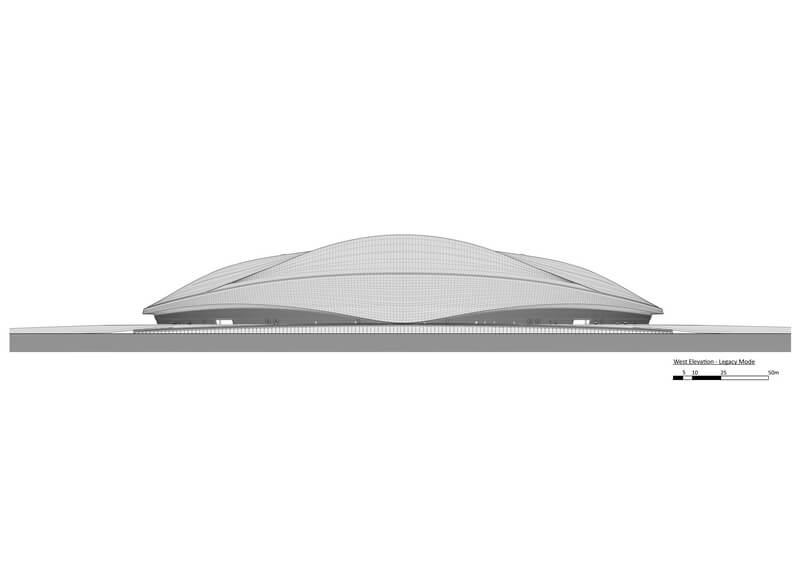

屋顶:被称为“眼梁”(Oculus Beam)的钢结构重达378吨,长约92m,它位于球场水平以上50m处,连接和支撑着整个屋顶,同时为结构的一些可伸缩部分提供维护通道。眼梁是在现场花费20多天的时间焊接和组装完成的。起初共有6个部件,在被吊装到位之前是搭建在临时框架上的。后期的焊接、拼装和安装过程共耗时40天。可伸缩屋顶借助钢线可在大约30分钟内完成关闭。处于闭合状态下的屋顶将为整个球场提供遮阳,并有助于提高体育场冷却系统的效果。(张萃 译)

Tournament capacity: 40,000

Distance from Doha city centre: 23km

Design: The design is inspired by traditional dhow boats, in tribute to Al Wakrah’s seafaring past. An innovative cooling system and retractable roof mean the stadium will be used all year round. The stadium was designed by Zaha Hadid.

Tournament mode: FIFA World Cup Qatar 2022™ quarter-finals venue.

Legacy mode: Home of Al Wakrah Sports Club. Thanks to its modular nature, the stadium’s capacity will be reduced to 20,000 after the tournament, with the excess seats – from the upper tier – being donated to football development projects overseas.

Precinct facilities: Various sporting facilities, including a cycling and running track, horse riding areas and other green spaces. In addition, there will be a marketplace and community facilities, such as a mosque and school.

Inauguration: The stadium will host the 2019 Amir Cup final on 16 May 2019.

Main contractor: Joint venture between MIDMAC, Sixco and PORR Qatar.

Project manager: KEO International Consultants.

Boosting the local economy: A number of Qatari companies have been involved with the delivery of Al Janoub Stadium in Al Wakrah City, including MIDMAC and PORR Qatar, Coastal, which has manufactured the stadium seats, and Sulb, which has manufactured the steel required for the stadium. More than 50% of the investment to build the stadium has supported the Qatari economy.

Cooling technology: Al Janoub Stadium in Al Wakrah City will benefit from innovative cooling technology powered by solar harvesting that has been designed and delivered by Qatari experts.

A heating, ventilation and air conditioning (HVAC) system powered from solar harvesting will cool the spectator areas using under-seat supply terminals at low velocities. More than 100 air ventilation units – split evenly between the lower and upper tiers – will serve the stadium bowl. The cooling source for the stadium bowl HVAC system will be chilled water from a district cooling system. The maximum speed flow at spectator level will be 1m/s.

The pitch cooling system comprises eight air handling units (AHU): four on the east side and four on the west. Each AHU feed will connect to a plenum that runs along the pitch below the spectator seating. This plenum then feeds a number of jet nozzles that supply air across the pitch and into the field of play. The maximum speed flow at pitch level will be 10m/s.

Transport: Al Janoub Stadium in Al Wakrah City is served by a network of new expressways and roads which provide easy access to residents and visitors to both Al Wakrah and Doha. The stadium will be served by Al Wakrah station on the Red Line of Doha Metro. The station is located 4.5km from the stadium and will be served by shuttle bus services on match days. The precinct has dedicated bus stops, interconnected cycling paths and safe pedestrian routes.

Sustainability: Al Janoub Stadium in Al Wakrah City has achieved three sustainability certifications:

1) Global Sustainability Assessment System (GSAS) Design & Build Certificate – 4-star for sustainable design

2) GSAS Construction Management Certificate Class A* sustainability rating, recognising the project’s extensive efforts to protect the environment during construction.

3) Seasonal Energy Efficiency ratio certificate for energy centre

The pitch: The turf used for the playing surface was grown at the Al Wakrah turf farm. The pitch was laid for the first time in March, in a record time of just 9 hours 15 minutes.

The roof: Weighing 378t and measuring 92m, the steel structure – known as an ‘oculus beam’ – sits 50m above pitch level It will connect and support the entire roof, while providing maintenance access to some of the retractable parts of the structure. The beam was welded and assembled onsite over 20 days. Originally six pieces, the structure was built on temporary frames before being lifted into place. The entire welding, assembly and installation process took 40 days. The retractable roof can close in approximately 30 minutes using a number of steel wires. The roof will provide shade to the entire pitch and contribute to the efficiency of the stadium’s innovative cooling system.