1 波浪纹面

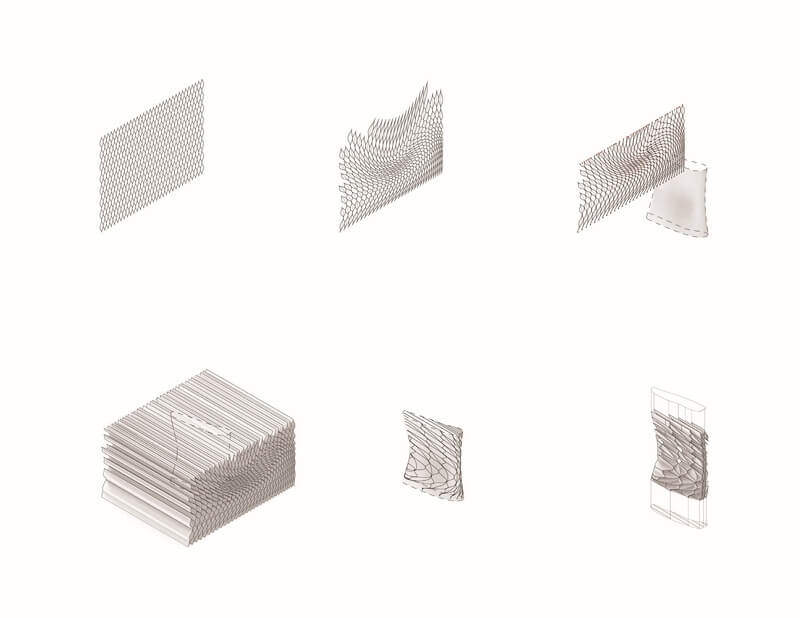

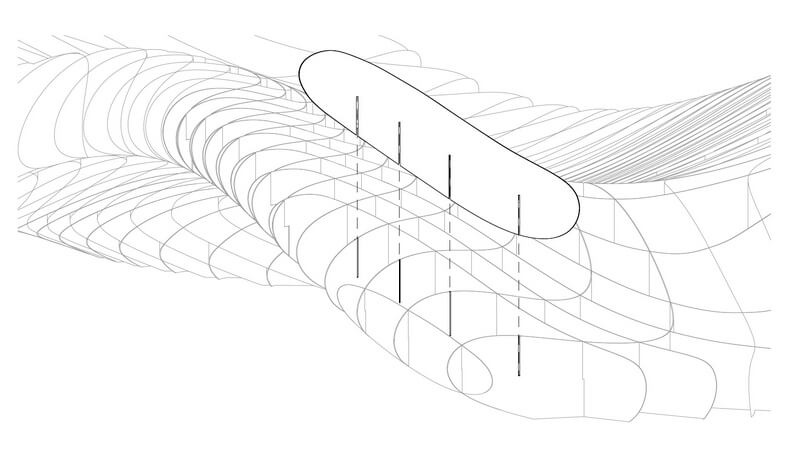

Orproject开发了一种基于单曲面基础而形成的复杂曲线的纹路板面,并且它的建造具有成本效益。它通过在平面上绘制相互连接的曲线场来生成几何图形:S形曲线蜂窝状排列,线条的曲率会在它们的连接点上持续,且其他组合也会有类似生成;然后曲线垂直向内拉伸,从而形成一个单曲面块。然后沿着一个3D双曲面自由曲面或体量(此处称为修剪几何体)裁剪原曲面块。在原单曲面块与双曲面体的交叉处,修剪表面的可见边缘便形成了一个复杂的自由曲线网络,近似于双曲面修剪几何(图1)。

图1 几何体生成过程

该系统类似于用“华夫饼”结构生成“类自由形态”的体量。然而华夫饼结构通常使用平面的、平行的平面区域来修剪实体体量,而波浪纹面则使用单曲面。所以当它们被设计成是连续链接时,修剪后的体积会产生“华夫饼”结构所缺失的延续曲线网络。

Orproject已将这种几何形状用于各种项目:从产品设计到装置,再到建筑设计概念。本文中,我们介绍了其中几个项目,并就其设计和施工等因素进行了比较分析。

2 项目介绍

2.1 Anisotropia 异向异态

Orproject和王欣的装置Anisotropia(异向异态)是在2011年为位于北京的中国国家博物馆建造的。它是由竹质单板制造而成,悬吊于天花板上。该装置的几何形状是通过水平对齐和拉伸曲线网络生成的。 复杂的表面网络构成一个如同墙一般的结构,它在一个方向上是通透的,而在另一个方向上是遮蔽的,从而创造或是阻挡视野,也进一步弱化了光线直射(图2)。

图2 Anisotropia 异向异态

2.2 瓣亭

瓣亭是2012年为北京的蓬蒿剧场所做的一个自支撑结构的尝试,材料依然是波浪纹面。它的中文名称是花瓣,类似于花瓣的弧度曲线,瓣亭即是由弯曲的聚合物片材所制。修剪体量构成了向内空间以及5个触地支撑点。为了创建承重结构,曲线平面水平放置并垂直挤压。由于板材几何形状无法抵抗悬垂区域的弯曲,因此在结构中引入了额外的圆柱。由此产生的瓣亭在透明和反射的相互作用下和它的背景几乎融为一体。当一个人坐在下方并向上看时,可以欣赏到S曲线网络的纹理样式(图3)。

图3 瓣亭

2.3 鲜系列

鲜系列是一个囊括水果碗和花瓶等的产品系列,于2015年受新德里的Art d'Inox委托设计。碗和花瓶均由独特的不锈钢条制成。鲜系列还在新德里的India Design(印度设计)中展出。

在水果碗的设计中,波浪条带水平垂面挤压,它沿着一个双曲面体量切割,有三个水平接触点形成;由此产生的几何形状是一个鳞片状的表面,它能极大减少与水果的接触。在花瓶的设计中,波浪纹面与水平平面垂直,它们横向挤压。同时设计还雕出一个内部空隙,以容纳玻璃管。修饰过的几何形状使花瓶有前后两个面,人们可在不同方向欣赏波浪板的复杂分层,表面网络变得通透,花茎可见(图4)。

图4 鲜系列

2.4 Anabond阿钠邦德集团

这个产品展位是为阿钠邦德集团设计的,用来展示他们的产品系列。该展位于2019 年首次安装在印度的哥印拜陀,然后于 2020年在新德里安装展示,2022年8月也将再次展陈。展亭的便携性需求使设计之初便对组装、包装和运输等进行过特殊的考虑。

展位由前墙和后墙组成。前墙有一个可延伸入展览空间的窗口,附以品牌标识,而后墙则用来展示集团的产品。在展位的设计中,波浪曲面营造出两种不同的线性:前墙的曲面垂直向挤压突出,以便引导视野进入展览空间,而后墙的曲面则是水平波动,以生成一个不透明的展陈背景。考虑到组装和运输需求,展位的设计是由三个组件组成,波浪纹面分段建造。弯曲的胶合板面由框架支撑,而额外的透明聚碳酸酯板则提供张力需求(图5)。

图5 阿钠邦德

2.5 Aggarwal精品店

这是为新德里的Amit Aggarwal服装品牌设计的精品店室内,它也是最长的波浪纹面装置,墙的总长约120m。这些墙面将商店划分为不同的部分,并引导用户游离于其中。波纹墙面既可以作为空间隔断,也可以作为陈列衣服的背景。聚碳酸酯板与反射膜层压在一起,在几何形状的曲率变化下形成多重反射,营造出了轻盈和神秘感。

与异向异态(Anisotropia)一样,波纹墙装置上面悬挂于天花板,地面固定在地板上。在异向异态中,因为重力原因,这种固定方式导致整体体态略微下垂,曲面上部绷得过紧。为防止这种情况发生,我们在这个设计中引入了一个额外的透明层,垂直跨越蜂窝单元。它提供承受结构的张力,将S形曲面维持原位(图6)。

图6 Amit Aggarwal 精品店

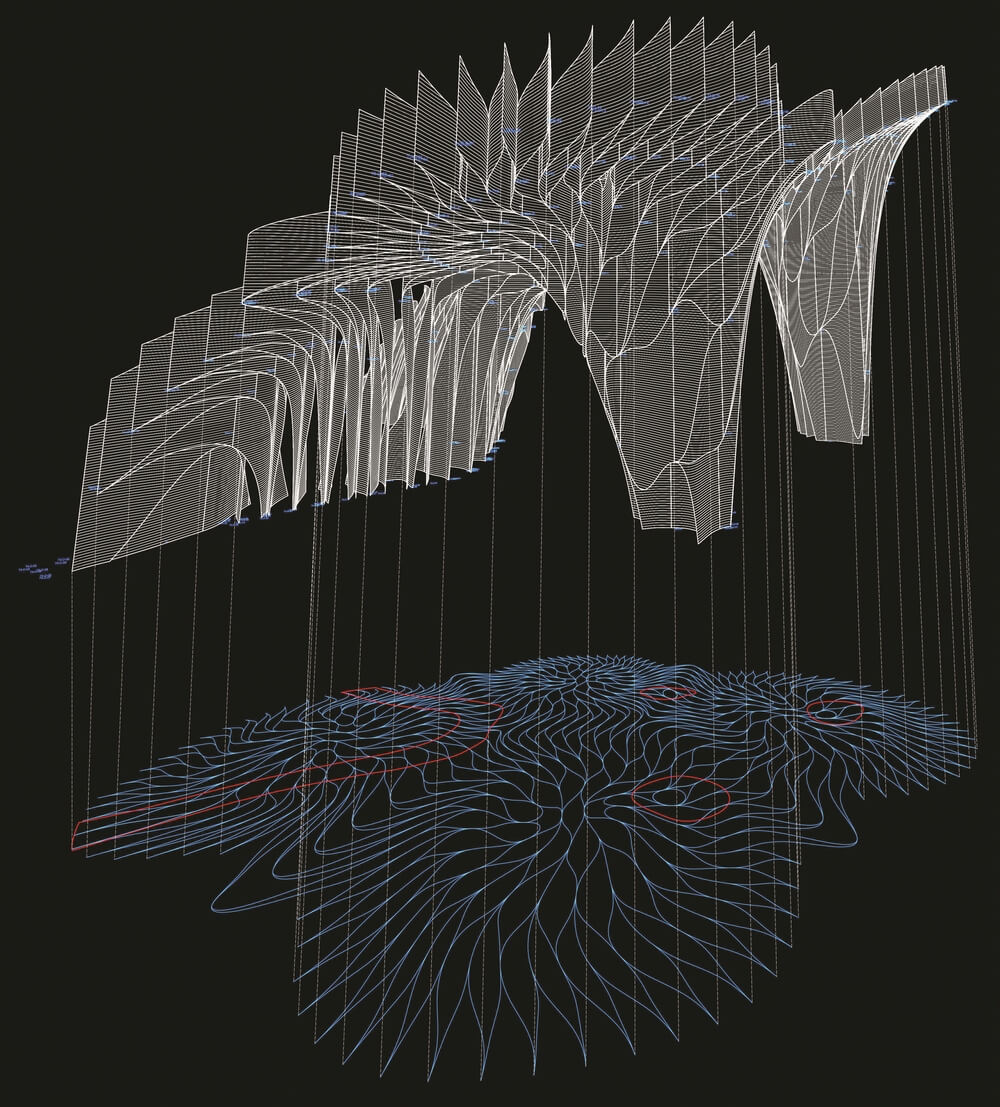

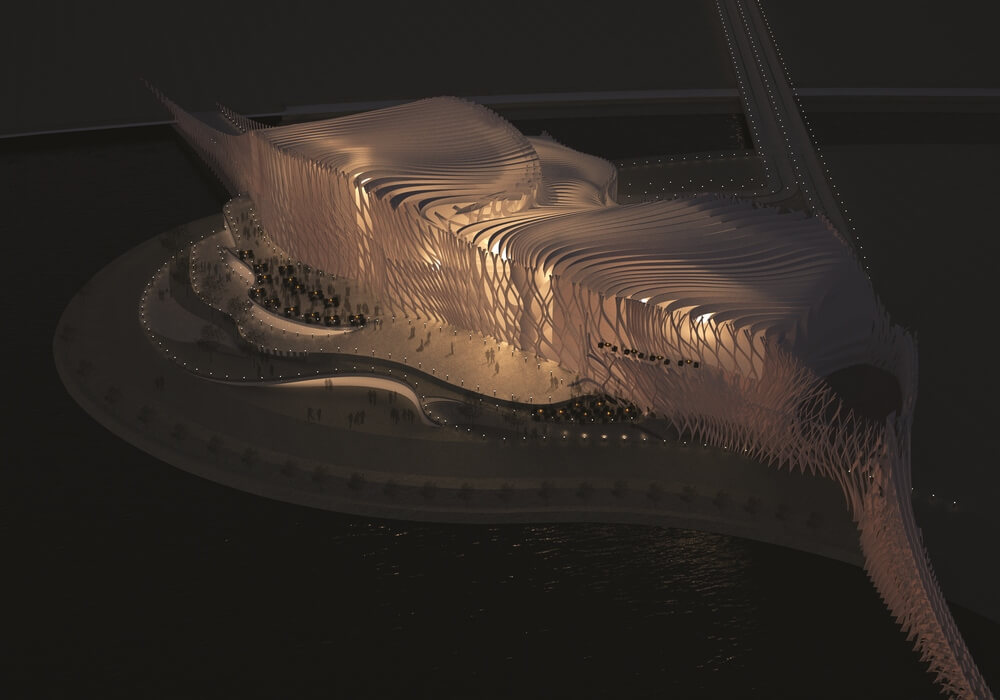

2.6 釜山歌剧院

该案例是2011年韩国釜山新歌剧院设计竞赛的参赛方案。虽未实现,但该方案被包括在此文内,用以说明该装置在更大规模项目中的可能性。在这个方案中,波浪板面结构用于外部钢结构以及内部干墙覆层。波浪纹面水平方向凸起,横跨主要内部空间的线性布局。因此,中庭向两侧开放,而礼堂则位于内部分隔墙后侧。

波浪板面形成了立面上垂直的钢结构,但随后幻化为横梁,延展于内部空间,连接不同立面。垂直结构由单曲面钢板焊接而成,最后形成波浪形的盒子。

在室内,相同的几何布局继续延伸为干墙系统。虽然由于水平方向的延伸挤压,沿立面的钢结构是开放的,相同线性流动也形成了主要内部空间的分隔墙。单曲面干墙板在建造上也能节省成本(图7)。

图7 釜山歌剧院

2.7 隈研吾设计的巴特罗公寓装置

无独有偶,我们在知名建筑师隈研吾设计的巴特罗公寓内部装置中,也看到了波浪纹面这一类似的想法。巴特罗公寓内的装修没有用波浪纹面的板材,而是从天花上悬挂下来很多铝制链条,形成波浪纹路。曲线的挤压矢量遵循其自身重力,每个链条精准定位于天花板上的曲线点位。

2.8 Sahya萨雅装置

该作品是在2016年威尼斯双年展中展出的一个几何装置,这次我们使用了一个不太一样的几何生成系统,它是波浪纹面板材的三维版式运用。基础几何曲面不是通过直线挤压而形成的,而是单个双曲面重复组合形成的。板面在轴线中重复而生成双曲线层,然后将其相互相邻堆叠,双曲率的高低点形成相邻层之间的接触点和连接点。在这个装置中不同层面以黑色和白色区别着色(图8)。

图8 萨雅

3 比较与分析

我们对以上项目基于几何、制作和性能等标准进行了比较。下方的表1概述了对比后的主要差异。这些项目的规模从产品到建筑设计不等,材料使用包括聚合物、金属和木材等。

3.1 规模

复杂的曲线网络、单曲面等已被广泛用于设计物件、墙壁、亭台和建筑物等。其中已实现的设计囊括,最小至0.1m(鲜系列)到最大5m的结构(异向异态,Aggarwal精品店);未实现的大型建筑提案比如釜山歌剧院。在不同的尺度上,蜂窝S形格子的尺寸都经过缩放,从而能够优化结构的完整性、实现建造材料的厚度、嵌套切割和组装方便。例如,鲜系列中的碗和花瓶使用的是1张0.35mm厚的不锈钢;萨雅的面板尺寸是根据当地可用的真空成型机而来的。对于阿钠邦德来说,胶合板的可弯曲度规定了格子中最小和最大S形曲线的尺寸。

3.2 方位

对于每个项目来说,三个方位上的关注是至关重要的:曲线网络的平面、拉伸方向和3D剪裁几何体的方位。这些方位的确定会根据每个项目性质不同而定制。方位的变化也会控制视野以及几何体的结构行为。

在釜山歌剧院的设计案例中,曲线网格面垂直于地面,并且其在地平面上的角度基于立面表面而变化。水平挤压的方式营造出外部景观,并且避免太阳眩光。设计利用材料沿挤压方向的连续性,生成了结构梁。一旦挤出的表面被3D体量套切,就会出现两种特性——复杂的曲线表面和“剥开”的表面。3D表面的方位决定了“蜂窝口”的深度和“剥开”的纹理(图9)。

图9 鲜系列中的“蜂窝口”和“剥皮”

在花亭中,处于结构原因,挤压方向是垂直向进行的,而在阿钠邦德和Aggarwal精品店项目中,挤压方向则是水平向的,目的是为了打开或者闭合墙体间的视野。

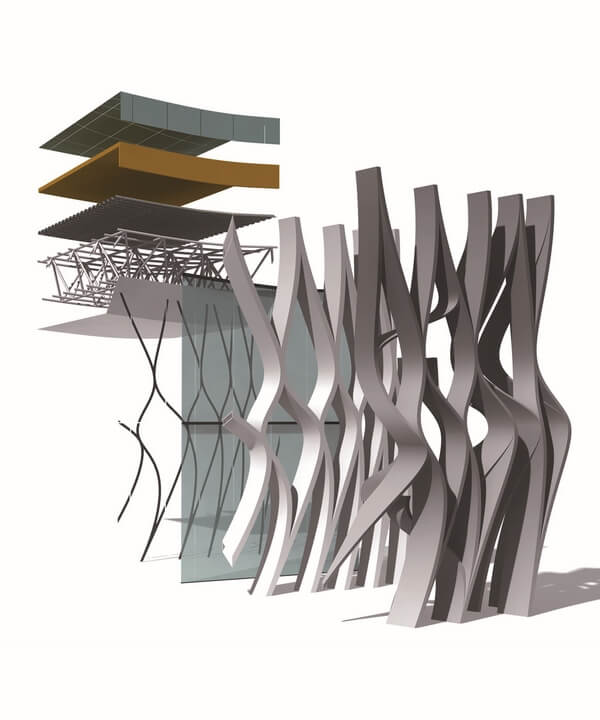

在激光切割和CNC铣床的使用下,这些波浪纹面可以用四种不同的材料实现,可具备三种不同的厚度。在一些项目中,它还使用了复合材料。材料的选择因其弹性和刚性而各有侧重:聚碳酸酯在弯曲后会弹回原来的形状;而可弯曲的胶合板会因自身重量而下垂,并且刚度较低;不锈钢材具有延展性,强度高,也可用作食品级/食品安全材料;ABS塑料是可模塑的,可真空成型以制造刚性面板,再通过CNC铣削成所需的组件;PETG可承受外部温度的变化,且非常耐用。而对于较大的建筑应用,则需选择钢和石膏板的组合(图10)。

图10 釜山歌剧院中的钢和石膏板组合细节

大多数材料的尺寸是1.2m×2.4m。如果是 ABS塑料,供应商可以定制面板的尺寸。 对于萨雅项目中的板面,扁平ABS塑料板受限于当地可用的真空成型机的框架尺寸、CNC铣削所需的间隙。

3.4 连接细节

针对波浪板所应用到的不同材料,材料板通常是一个挤压的S形段,在曲线段的交叉点处做连接。如何连接则是由材料、材料厚度及其结构规模所决定的。

对于较大的项目,一般都是运用钢螺栓连接细节。垫圈的材料厚度由连接处材料的厚度决定。以萨雅项目中所运用的ABS 塑料为例,橡胶垫圈用于调整模制面板之间的局部曲率变化。螺栓的长度由在曲线网络的任何一个交点处所需的一系列垫圈和材料片来决定。在某些情况下,2块组件发生连接,在某些情况下是4块组件需要连接,最多的时候是需要连接8个板面,所以螺栓长度需要相应调整。此外,在大多数情况下,相互连接的层板的厚度是相同的,但在阿钠邦德项目中,我们需要考虑两种材料的不同厚度:可弯曲胶合板(12.5mm)和聚碳酸酯板(2mm)。打孔是通过激光切割,或用数字生成的模板铣削。

对于由不锈钢制成的较小规模的鲜系列产品,我们是在不锈钢带之间设计了一个互锁的半搭接口。在这里,蜂窝格中的S形曲线并不总是相切排列。基于网格曲线的变形,半搭接的宽度通常是材料的厚度(在这种情况下为0.35mm),最终的宽度高达35mm,是材料厚度的100倍。在夹具上组装好后,这些接头会用粘合剂固定(图11)。在鲜系列中的花瓶中,互锁的接缝头是在一层圆的3/4处切口与另一层之间。然后用一个小金属圈弯曲以形成插口,插入连接条上的孔并卡到位。

图11 鲜系列碗产品的半搭接细节

3.6 结构表现

不同的项目使用了不同类型的结构配置。 最简单的方式是拉伸结构,例如在异向异态和Aggarwal精品店项目中:波浪板悬挂在天花板上,和固定在地面上。但挑战是,比如在异向异态中,波浪纹面板在其自身重量下的矫直。因此在Aggarwal精品店中我们便使用了第三层透明材质,该材料直接穿过每个蜂窝单元。这些片材比S形段材更笔直,它们保持弯曲片材维持其位置的同时,也承受张力。

在小规模上,鲜系列产品实现了一种承重结构,其中钢材的刚度可抵抗过度变形。 瓣亭也进行了类似的尝试,垂直向的挤压可以提供结构上的支撑;但与此同时又会出现悬垂,因此设计在必要地方引入了管道,相当于平面中圆形曲线的挤压。

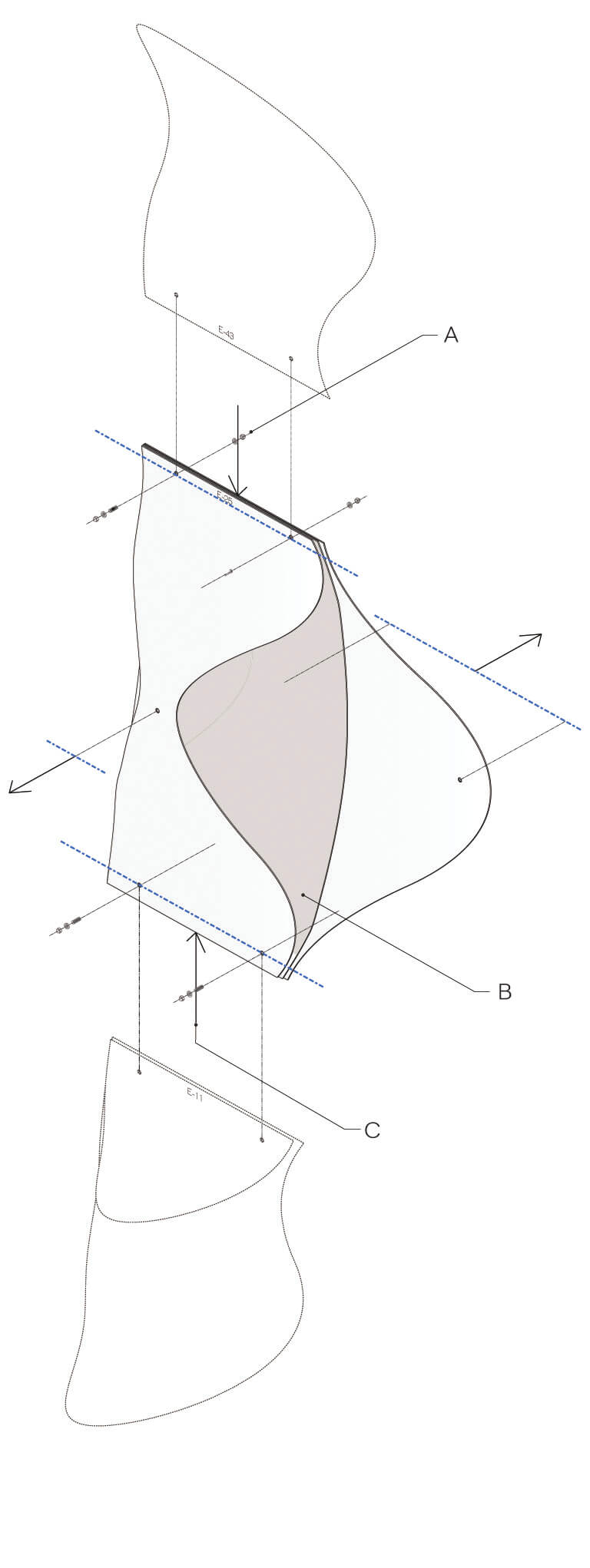

针对阿钠邦德项目,我们测试了一个由受压可弯曲胶合板和受拉聚碳酸酯板组成的复合结构(图12)。这些面板连接到一个主要的金属框架中,以确保结构的稳定性和精确定位。

图12 受压网格弯曲板面(A),受拉中间层(B)和叠加边缘(C)

3.7 体验感

在釜山歌剧院、异向异态、Aggarwal精品店和阿钠邦德集团项目中,波浪纹面板材充当一种垂直平面,并被视为带有格子窗的墙状结构。墙壁的透明和不透明唤起了观者观看雕塑般的体验,曲线的复杂性随着视角的变化而变化。反射、材料纹理和纹路也增强了这些墙元素的视觉体验(图13)。当人们绕着这些墙壁移动时,它的透明度会随之变幻,一些角度呈现出非透明,而另一些视角则完全打开不同的画面。此外,如将物体放置在这些墙元素前,物体边缘会感觉更加突出。该墙体的薄度惊人,给人一种具备丰盈细节的浮动薄片感。

图13 Aggarwal精品店的波浪纹面板材

就瓣亭而言,它给人一种无定形的、模糊的和涣散的感觉,看起来透明但实则又非然。弯曲的PETG面板扭曲、折射光线,形成了这种不清晰的画面感。当观者接近它并走到悬臂下方时,就会发现那有组织的图案排列布局如花瓣一般(图14)。这种从不确定到高度组织的转变过程,形成一种充实的审美体验。

图14 瓣亭

萨雅的整体感觉像是由移动的波浪纹理板面组成。面板的交替分层创造了一种悬浮感。靠在黑色面板上的白色面板看上去像是有弧度地向外延伸,似漂浮于空中。当你从装置旁边经过时,它的实体似乎消失了,因为你的视线能穿透整个结构。实体的坚固性与这些深格子空隙的反差挑战了观者的预期。

4 结论

以S形面板的排列方式建造双曲线体量的方法是一种具有成本效益的建造方式。 该组合通过其在规模、方向和材料等方面的灵活性,实现了双曲率的一系列不同表达。价格适宜的施工细节和基于矩阵的装配系统省时地建造了这种结构。

由于单曲面表面沿着双曲线体块进行了修剪,因此所有的项目都具有共同的流动感。由此生成的复杂空间曲线网络是高度动态的,非重复的。复杂的轮廓曲线边缘形成了可见性、材料特性、神秘感和亮度等的发差和变化,增强了几何形状的体验感。

Orproject已尝试将这种几何形状用于各种类型的项目中:从产品设计到装置,再到建筑设计的概念方案。我们憧憬未来能将它开发和部署到更大规模的项目上。

参考文献:

[1] Iwamoto, L., 2013. Digital fabrications: architectural and material techniques. Princeton Architectural Press.

[2] Koppitz, J.P., Quinn, G., Schmid, V. and Thurik, A., 2011. Metropol parasol-digital timber design. In Computational Design Modelling (pp. 249-257). Springer, Berlin, Heidelberg.

[3] Klemmt, C., 2012. Anisotropia-Movements towards a Lyrical Design. Electronic Visualisation and the Arts (EVA 2012), pp.286-292.

[4] Arribas Sánchez, C., 2021. La cultura serà immersiva o no serà?. L'Informatiu del Col· legi d'Aparelladors i Arquitectes Tècnics de Barcelona, (369), pp.114-123.

[5] Klemmt, C. and Sodhi, R., 2017. Double-Curved Form Approximation with Identical Discrete Panel Geometries.

项目信息:

Anisotropia 异向异态

建筑师: Xin Wang and Orproject

项目团队: Shuai Yang, Duan Duan, Haobin Lee

拍摄: Zhang Lu

瓣亭

建筑师: Orproject

项目经理: Shuai Yang

项目团队: Kevin Wang, Marian Ma, Qiuwen Shi

拍摄: Jasper James and Orproject

赞助商: SK Chemicals, Penghao Theatre

鲜系列

建筑师: Orproject

项目设计师: Rajat Sodhi

项目团队: Sambit Samant

客户: Art d'Inox

制造商: Rachaita Creative Solutions

拍摄: Sumedh Prasad

Anabond阿钠邦德集团

建筑师: Orproject

项目设计师: Rajat Sodhi, Christoph Klemmt

拍摄: Anand Jaju

Wall System for Aggarwal精品店

Interior Design: AVA Studio

墙体系统设计: Orproject

项目总监: Christoph Klemmt, Rajat Sodhi

建筑师: Ananya Kango

项目团队: Balaji Mohan Rajkumar, Komalpreet Kaur Sodhi

室内设计: Ava Studio

模型: Radhika Bopaiah

风格造型: Pushkin Bhasin

拍摄: Orproject, Shovan Gandhi, Suryan & Dang

釜山歌剧院

建筑师: Orproject

项目团队: Ho-Ping Hsia, Christoph Klemmt, Rolando Rodriguez-Leal, Rajat Sodhi, Natalia Wrzask, Christine Wu

结构工程师: Arups Structural Engineering, London

剧院顾问: Arups Theatre Consulting, Hong Kong

拍摄: Orproject

隈研吾设计的巴特罗公寓装置

建筑师: Kengo Kuma and Associates

Sahya萨雅装置

建筑师: Orproject

项目建筑师: Christoph Klemmt, Rajat Sodhi, Haseb Zada

项目团队: Abhinav Chaudhary, Sambit Samant

拍摄: Valerie Bennett, Orproject

拉杰·索迪 Orproject事务所合伙人

克里斯托弗·克莱姆 Orproject事务所合伙人

美国辛辛那提大学副教授

翻译:张萃

1 Waving Sheets

Orproject has developed a type of geometry based on single-curved surfaces that results in networks of intricate curves, yet is cost-effective to construct. The geometries are generated by drawing an interconnected field of curves on a plane. A honeycomb arrangement of S-shaped curves results in intricate geometries as the curvature of the lines continues across their connection points, however, other arrangements are similarly possible. The curves are then extruded normal to the plane of the curves, resulting in a block of single-curved surfaces. This block of surfaces is then trimmed along a 3D double-curved free-form surface or volume, here referred to as the trim geometry. The visible edges of the trimmed surfaces, at the intersection of the single-curved surfaces with the double-curved trim geometry, form an intricate network of free-form curves that approximate the double-curved trim geometry (Figure 1).

The system is similar to waffle structures that are used to approximate free-form volumes [1,2]. However, whereas waffle structures commonly use a field of flat, parallel planes from which the solid volume is trimmed, the Waving Sheets use single-curved surfaces. Especially when those are designed to be continuous across the connection points, the trimmed volume results in the network of continuous curves that a waffle structure lacks.

Orproject has used this type of geometry for a variety of projects, ranging from product design to installations to unrealized building designs. In this paper we present several of those projects and provide a comparative analysis regarding a variety of design and construction considerations.

2 Projects

2.1 Anisotropia

The installation Anisotropia, by Orproject and Xin Wang, was constructed for the National Museum of China in Beijing in 2011 [3]. It is made from sheets of bamboo veneer that are suspended from the ceiling. The geometry of this installation is derived by aligning and extruding the network of curves horizontally. The intricate network of surfaces result in a wall like installation which is transparent in one direction and opaque in the other, thereby creating or blocking views and diffusing light (Figure 2).

2.2 Ban

The pavilion Ban was an attempt to use the waving sheets geometry for a self-supporting structure, constructed for PengHao Theatre in Beijing in 2012. The chinese title refers to flower petals, and similar to the way that the shape of a flower is created by its bent petals, Ban is constructed from bent polymer sheets. The trimming volume creates interior spaces as well as 5 positions for ground support. In order to create the load-bearing structure, the plane of curves is placed horizontally and extruded vertically. As the sheet geometries are unable to resist bending in areas of overhangs, additional circular columns were introduced into the structure. The resulting pavilion blurs into its background through an interplay of transparencies and reflections. As one sits below and looks above, one can appreciate the patterns of the S-curve network (Figure 3).

2.3. Umami

Umami is a product series that consists of a fruit bowl and a flower vase that was commissioned and designed for Art d’Inox in New Delhi in 2015. Both the bowl and the flower vase are constructed from unique stainless steel strips. The Umami series was exhibited at India Design in New Delhi.

In the case of the fruit bowl, the waving strips structure is extruded normal to the horizontal plane and this is trimmed along a double-curved volume that touches the horizontal plane in three places. The resulting geometry is a scaly surface that minimises contact with the fruit. For the flower vase the plane of the waving curves geometry is perpendicular to the ground plane and these curves are extruded horizontally. Additionally an internal void is carved out to accommodate a glass tube. In the case of the flower vase the trimmed geometry creates a back and front aspect to the vase where one can appreciate the complex layering of the waving sheets in one direction and in the other direction, the network of surfaces becomes transparent and the stalks of the flowers are made visible (Figure 4).

2.4 Anabond

This trade-fair stall was designed for company Anabond to showcase their range of products. The stall was first installed in Coimbatore in 2019, then at New Delhi in 2020 and is going to be exhibited again in August 2022. This portability aspect of the design required special considerations for assembly, packaging and transportation.

The stall consists of a front and a back wall. The front wall creates a window into the exhibition space and carries the brand’s identity and logo, whilst the rear wall showcases the products. For the design of the stall the waving curves were placed in two different orientations: The curves of the front wall were extruded perpendicular to the wall in order to allow views into the space, while the curves of the back wall were extruded along the wall to create an opaque background for the display. The stall is divided into three sections from the consideration of packaging and transport, so the waving surfaces are built in sections. The bent plywood surfaces are supported by a frame, while additional clear polycarbonate sheets provide tension (Figure 5).

2.5 Boutique Aggarwal

For the flagship store of Amit Aggarwal in New Delhi, we had to develop the longest setup of the waving walls. The total wall length of these walls is approximately 120 metres. These walls divide the store in different sections and guide the users through them. The walls serve both as spatial partitions and as the background against which the clothes are arranged. The sheets of polycarbonate are laminated with a reflective film that creates multiple reflections through the curvatures of the geometry, thereby creating a sense of lightness and mystery.

As in Anisotropia, the walls were hung from the ceiling and anchored on the floor. In Anisotropia, this caused a slight drooping of the geometry, as the weight of the material pulled downwards and thereby straightened the upper sections of the curves. In order to prevent this, additional clear layers were introduced that span vertically straight across one honeycomb cell. Those layers take the tensile force of the structure and keep the s-shaped curves in their position (Figure 6).

2.6 Busan Opera House

This project was a competition entry for the new opera building in Busan, South Korea, developed in 2011. While not constructed, the project was included to highlight the larger-scale possibilities of the system. For this project, the waving sheets structure was used for the outer steel structure as well as for the interior drywall cladding. The extrusion direction is horizontal, placed across the linear layout of the main interior spaces. As a result, the atrium opens up towards both sides, while the auditoriums are positioned behind interior separating walls.

The waving sheets form the steel structure that is vertical on the facades, but then merges into beams that span across the interior spaces from facade to facade. The vertical structure is welded out of single-curved steel sheets, resulting in waving boxes.

On the interior, the same geometry layout is continued as a drywall system. While the steel structure along the facade is open due to the horizontal orientation of the extrusion direction, the same orientation forms the dividing walls between the main interior spaces. Single-curved drywall panels allow for a cost-effective construction (Figure 7).

2.7 Kengo Kuma Casa Batlló

In a rather unfortunate move, architect Kengo Kuma decided to plagiarise the Waving Sheet geometric system developed by us for his design of Casa Batlló in Barcelona, Spain [3]. While the unauthorised copying of our work by Kengo Kuma constitutes a disappointing lack of creativity, we do acknowledge his interesting method for the construction of the geometries. Instead of a construction from sheet material as in all of our projects, Casa Batlló utilises a series of chains hanging from the ceiling for the materialisation of the forms. The extrusion vector of the curves therefore follows gravity, and each chain hangs straight down from its position on the curves underneath the ceiling.

2.8 Sahya

The installation Sahya, constructed for the Venice Biennale 2016, uses a slightly different system for the generation of the geometry, a three-dimensional version of the Waving Sheets [5]. Instead of single-curved surfaces created by extruding a curve straight, the geometry is based on individual double-curved panels in two repetitive shapes. The panels are repeated in a grid to form a double-curved layer. Several layers are stacked adjacent to each other, so that the high and low points of the double curvature form touching points and connections between adjacent layers. For Sahya, the layers were coloured alternatingly black and white (Figure 8).

3 Comparison and Evaluation

The projects have been compared according to a variety of geometric, fabrication and performance criteria. Table 1 gives an overview of the main differences. The projects range in scale from product to building design and use materials such as polymers, metals and timber.

| Anisotropia | Ban | Umami Bowl/ Vase | Anabond | Boutique Aggarwal | Busan Opera | Casa Batlló | Sahya | |

| Height | 5m | 3m | 0.1m / 0.4m | 2.5m | 2.4m | 42 m | 1.6m | |

| Material | Bamboo Veneer | Petg | Stainless Steel | Bendable Plywood And Polycarbonate Sheets | Laminated Polycarbonate Sheets | Steel / Gypsum Board | Metal Chains | Custom Moulded Abs Plastic |

| Joints | M3 Bolts | M4 Bolts | Interlocking Joint | M3 Bolts | M3 Bolts | Welded / Drywall Screws | N/A | M4 Bolts |

Extrusion Direction | Horizontal | Vertical | Vertical/Horizontal | Horizontal | Horizontal | Horizontal | Vertical | N/A |

| Structure | In Tension | Load Bearing | Load Bearing | Not Load Bearing | In Tension | Load Bearing / Not Load Bearing | In Tension | Load Bearing |

Table 1: Project Comparison

3.1 Scale

The intricate network of curved lines, single-curved surfaces has been used to design objects, walls, pavilions and buildings. The realised designs vary from objects as small as 0.1 m (Umami) to as large as 5 m (Anisotropia, Amit Aggarwal Boutique), with unrealized proposals for large buildings (Busan Opera House). At each scale, the size of the honeycomb S-shaped lattice is scaled to optimise structural integrity, thickness of the material used to build it, nested cutting and ease of assembly: The series for umami bowl and vase were manufactured using 1 sheet of 0.35 mm thick stainless steel. The panel size for Sahya was restricted by locally available vacuum forming machines. For Anabond, the limits of the bendability of the plywood restricted the size of the smallest and largest S-shaped curve in the lattice.

3.2 Orientation

For each project, three orientations are crucial for the design - the plane of the network of lattice curves, the extrusion direction, and the orientation of the 3D trim geometry. The determination of these orientations are customised by the nature of the projects. The orientations have been used to control views as well as structural behaviours of the geometry.

In the case of the design of Busan Opera House, the network of lattice curves is placed perpendicular to the ground plane and varies in its angle on the ground plane based on the facade surface. The direction of horizontal extrusion can be used to create views of the outside or to avoid solar glare. At the same time, the continuity of the material along the extrusion directions is utilised to form structural beams. Once the extruded surfaces are trimmed by a 3D surface, two qualities appear - the intricate surface of curves and “peeling” surfaces on the other side. The orientation of the 3D surface determines the depth of the “windows” and the amount of the “peel” (Figure 9).

In Ban, the extrusion direction is placed vertically for structural reasons, while in both Anabond and the Amit Aggarwal Boutique, the horizontal directions are used to open up or block views across the walls.

3.3 Material

These Waving Sheet objects have been materialised in four different materials and three thicknesses using laser cutting and CNC-milling machines. In some projects, a composite of materials has also been deployed. The materials are used for their elastic properties and rigidity. Polycarbonate springs back to its original shape when bent, whilst bendable plywood can collapse under its own weight and has a low rigidity. Stainless steel is malleable, has high strength and also can be used for projects where food-grade / food-safe materials are required. ABS plastic is moldable and can be vacuum formed to create rigid panels that can be CNC-milled into desired components. PETG can withstand variations in outside temperature and is highly durable. For larger architectural applications, a combination of steel and gypsum board has been designed (Figure 10).

Most materials are readily available in 1.2 m x 2.4 m size. However in the case of ABS plastic, the suppliers can custom mould the size of the panels. For Sahya, the flat ABS plastic sheets were determined by the size of the locally available vacuum forming machine frame size and clearances required for CNC-milling.

3.4 Connection Details

For the materisation of the waving sheets, panels are commonly designed to form one extruded, S-shaped segment, with connections at the intersection points of the curve segments. The connection details are determined by the materials, the material thickness and the scale of the structure.

For the larger projects, mostly steel bolts were used for the connection details. The thickness of material of the washer is determined by the thickness of the materials connected. In the case of Sahya, which was made from ABS plastic, rubber washers were used to adjust for changing local curvature between the moulded panels. The length of the bolts is determined by the series of washer and sheets of material required at any one intersection point of the network of lattice curves. In some places, 2 parts connect, in some places 4 parts, and in some places up to 8 sheets may be connected, with bolt lengths adjusted accordingly. Additionally, in most cases the connected layers are of the same thickness, but in the case of Anabond, the thickness of two layers - bendable plywood (12.5 mm) and polycarbonate sheets (2 mm) are considered. The holes are laser cut or milled via the digitally generated templates.

For the smaller scale Umami series from stainless steel, an interlocking half lap joint is created between the stainless steel strips. Here the S-shaped curves in the lattice are not always arranged tangentially to one another. Therefore based on the distortions of the lattice curves, the width of the half lap, which is usually the thickness of the material (0.35 mm in this case), results in widths as large as 35 mm, 100 times the material thickness. Once assembled on the jig, these joints are attached using an adhesive (Figure 11). In the case of the Umami vase, an interlocking flat lock seam joint is created between the layers where ¾ circles are cut in one sheet and a hole is cut in the other. The small metal circles are then bent to create a seam, inserted through the hole in the connecting strip and then snap-locked in place.

3.6 Structural Performance

Different kinds of structural configurations have been used in the projects. The easiest application was in tension, as in the projects Anisotropia and Amit Aggarwal Boutique. Here the waving sheets are suspended from the ceiling and anchored to the ground. A difficulty was the straightening of the sheets under their own weight as occurred in Anisotropia. The Amit Aggarwal Boutique therefore utilised the above mentioned third layer of transparent material that passes straight across each honeycomb cell. Those sheets are more straight than the S-shaped segments and therefore take the tension while keeping the curved sheets in their position.

At the small scale, a load-bearing structure was achieved with Umami, where the stiffness of the steel material resists excessive deformation. A similar attempt was made for Ban, where the extrusion was placed vertically to provide structural support. As this caused difficulties in areas of overhang, pipes were introduced where necessary, designed as the extrusion of circular curves in plan.

For Anabond, a composite structure of bendable plywood in compression and polycarbonate sheets in tension has been tested (Figure 12). These panels are attached to a primary metal frame, which ensures the stability and precise positioning of the structure.

3.7 Experiential Qualities

In Busan Opera House, Anisotropia, Amit Aggarwal Boutique and Anabond, the curved surface is experienced as a vertical plane and is perceived as a wall like structure with lattice windows. The transparency and opacities of the wall evoke the experience of looking at a sculpture, the intricacies of the curves changing with the change of the viewpoint. Reflections, material textures and grains also enhance this visual experience of these wall-elements (Figure 13). As one moves around these walls, the transparencies through the structure change as some views become opaque whilst other new views open up in a different direction. Additionally, when objects are placed in front of these wall-elements, the edges of those objects feel more defined against the background of the walls. The impossible thin-ness of the structures stands out, giving the feeling of floating lamellas with intricate detail.

In the case of BAN, one encounters the pavilion as an amorphous, unclear and blur-object that seems transparent but is not. The curved PETG panels distort and refract light to support this unclear imagery. As one approaches the pavilion and encounters the underside of the cantilevered roof like surface, the organised pattern of sheets is revealed as an arrangement of flower petals (Figure 14). This shifting experience from undefined to highly organised is a fulfilling aesthetic experience.

Sahya presents itself as an object formed out of moving waves. The alternate layering of the panels creates a sense of suspension. The white panels placed against black panels appear to be curving out and floating in mid air. When moving around the installation, the solidity of the object disappears as one can glance through the structure. The contrast of solidity against these deep lattice voids also challenges the expectations of the viewers.

4 Conclusions

The method of building double curved volumes as an arrangement of S-shaped panels is a cost efficient way of construction. This system enables a series of expressions for double curvature through its flexibility in scale, orientation and material. Using inexpensive construction details and a matrix based assembly system, the structures can be built in a time-efficient way.

All projects have a fluidity in common as the result of the single-curved surfaces that have been trimmed along double-curved volumes. The resulting complex spatial curve networks are highly dynamic and non-repetitive. The intricately contoured curve surface edges enhance the experience of the geometries using contrast in visibility, material properties, mystery and lightness.

Orproject has used this type of geometry for a variety of projects, ranging from product design to installations to unrealized building designs. We envisage further development and deployment in larger-scale projects.

References:

[1] Iwamoto, L., 2013. Digital fabrications: architectural and material techniques. Princeton Architectural Press.

[2] Koppitz, J.P., Quinn, G., Schmid, V. and Thurik, A., 2011. Metropol parasol-digital timber design. In Computational Design Modelling (pp. 249-257). Springer, Berlin, Heidelberg.

[3] Klemmt, C., 2012. Anisotropia–Movements towards a Lyrical Design. Electronic Visualisation and the Arts (EVA 2012), pp.286-292.

[4] Arribas Sánchez, C., 2021. La cultura serà immersiva o no serà?. L'Informatiu del Col· legi d'Aparelladors i Arquitectes Tècnics de Barcelona, (369), pp.114-123.

[5] Klemmt, C. and Sodhi, R., 2017. Double-Curved Form Approximation with Identical Discrete Panel Geometries.

Project Credits

Anisotropia

Architects: Xin Wang and Orproject

Project Team: Shuai Yang, Duan Duan, Haobin Lee

Photographs: Zhang Lu

Ban

Architects: Orproject

Project Manager: Shuai Yang

Project Team: Kevin Wang, Marian Ma, Qiuwen Shi

Photographs: Jasper James and Orproject

Sponsors: SK Chemicals, Penghao Theatre

Umami

Architects: Orproject

Project Designer: Rajat Sodhi

Project Team: Sambit Samant

Client: Art d'Inox

Manufacturer: Rachaita Creative Solutions

Photographs: Sumedh Prasad

Anabond

Architects: Orproject

Project Designer: Rajat Sodhi, Christoph Klemmt

Photographs: Anand Jaju

Wall System for Amit Aggarwal Flagship Store

Interior Design: AVA Studio

Wall System Design: Orproject

Project Directors: Christoph Klemmt, Rajat Sodhi

Project Architect: Ananya Kango

Project Team: Balaji Mohan Rajkumar, Komalpreet Kaur Sodhi

Model: Radhika Bopaiah

Stylist: Pushkin Bhasin

Photographs: Orproject, Shovan Gandhi, Suryan & Dang

Busan Opera House

Architects: Orproject

Design Team: Ho-Ping Hsia, Christoph Klemmt, Rolando Rodriguez-Leal, Rajat Sodhi, Natalia Wrzask, Christine Wu

Structural Engineers: Arups Structural Engineering, London

Theatre Consultants: Arups Theatre Consulting, Hong Kong

Images: Orproject

Casa Batlló

Architects: Kengo Kuma and Associates

Sahya

Architects: Orproject

Project Architects: Christoph Klemmt, Rajat Sodhi, Haseb Zada

Design Team: Abhinav Chaudhary, Sambit Samant

Photography: Valerie Bennett, Orproject

Rajat Sodhi, Partner, Orproject

Christoph Klemmt, Partner, Orproject;

Assistant Professor, University of Cincinnati